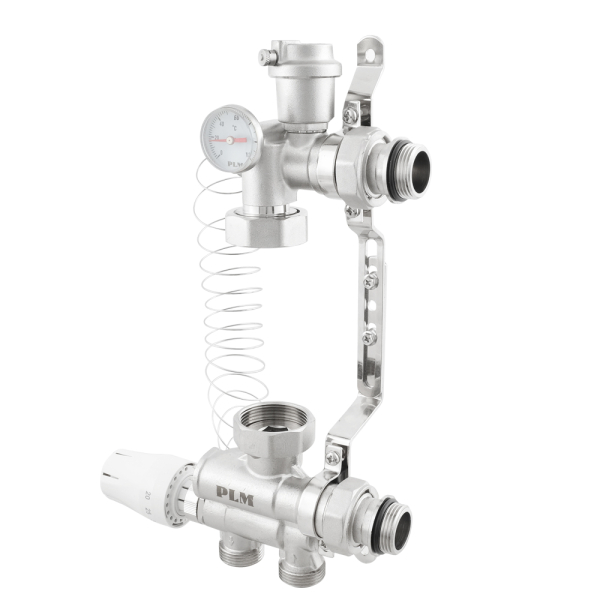

Mixing unit

Mixing Units for Underfloor Heating Systems are key elements that allow for the regulation of the heat carrier temperature to maintain an optimal microclimate. They not only provide comfort but also reduce energy costs, making them a popular solution in modern heating systems.

Purpose of the Mixing Unit

The mixing unit controls the temperature of the heat carrier. This device lowers the temperature of the hot water from the main heating system by mixing it with cooler water from the return line. This helps prevent overheating of the floor surface and maintains a stable temperature in the room.

Main Elements of the Mixing Unit

Mixing units typically consist of the following components:

- Thermostatic Valve — ensures the regulation of the heat carrier temperature according to specified parameters.

- Circulating Pump — responsible for the constant movement of the heat carrier throughout the circuit, ensuring uniform heating.

- Safety Valve and Thermometer — monitor pressure and temperature, protecting the system from overload.

- Thermal Head — designed to be installed on the thermostatic valve and regulates the user-defined temperature of the heat carrier.

Mixing Units from PLM

PLM's products, including mixing units, are made from high-quality materials that ensure resistance to corrosion and a long service life. PLM units are suitable for systems of any complexity, and they are easy to install and maintain.

Main Advantages of Units from PLM:

- Resistance to High Temperatures — thanks to sturdy materials, they can operate even in challenging conditions.

- Energy Efficiency — allow for reduced energy costs while maintaining a constant temperature.

- Long Service Life — the units are designed for stable operation and have a long-lasting resource.

How to Choose a Mixing Unit?

When choosing a mixing unit, it is important to consider:

- The capacity of the circulating pump.

- Operating pressure.

- Connection diameter.

Some models may be equipped with additional elements for more precise temperature control, which is particularly useful for larger areas.

Advantages of PLM Mixing Units

PLM Mixing Units are perfect for creating a comfortable microclimate in homes or offices, ensuring reliability, durability, and ease of use. Due to their characteristics, PLM units help in the efficient use of energy and have an excellent quality-to-price ratio, making them an especially attractive choice.

Advantages of PLM Units:

- Ease of Installation — can be installed in existing systems.

- Reliability and Safety — thanks to a well-thought-out design.

- Energy Savings — ensures reduced heating costs.

- Stable Operation — precise regulation and reliable design ensure long-lasting and stable operation.