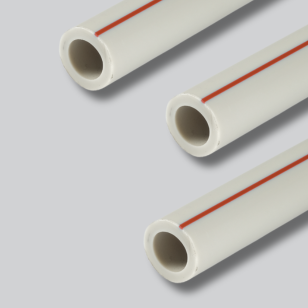

Water pipes

PPR (polypropylene) pipes and fittings are a convenient and cost-effective solution today for the installation of water supply and heating systems. Thanks to their unique characteristics, these systems have become popular among builders and homeowners. In this article, we will discuss the main advantages of the PPR system, its applications, and key selection factors.

What is the PPR system?

PPR pipes are made from polypropylene – a material known for its high resistance to chemical and physical influences, is non-corrosive, and ensures the durability of water supply and heating systems. PPR fittings are used to connect pipes and create tight and reliable systems.

Advantages of PPR systems

- Long service life. PPR pipes and fittings have a lifespan of up to 50 years. Thanks to their high resistance to aggressive environments and corrosion, the system remains reliable and stable for decades.

- Resistance to high temperatures. PPR pipes can withstand temperatures of up to 95°C - an excellent solution for use in hot water supply systems.

- Eco-friendliness and safety. Polypropylene does not interact with water, making PPR pipes safe for transporting drinking water. This material does not emit harmful substances, making it an environmentally friendly solution.

- Smooth inner surface. The inner walls of PPR pipes are smooth, preventing the formation of deposits and ensuring free water flow. This increases system efficiency and reduces the risk of blockages.

- Resistance to pressure fluctuations. PPR pipes can withstand significant pressure fluctuations without the risk of deformation or damage, making them a reliable solution for systems with high demands.

Use of PPR in water supply and heating

PPR systems are widely used in various fields:

- Hot and cold water supply. Due to their high resistance to temperature fluctuations, PPR pipes are ideal for both hot and cold water supply.

- Heating systems. PPR pipes can withstand high temperatures, making them suitable for central heating and underfloor heating systems.

- Industrial facilities. Due to their chemical resistance, PPR systems are used in industrial installations for transporting technical fluids and other media.

Key selection factors for PPR systems

When choosing PPR pipes and fittings, several important factors should be considered:

- Pipe diameter. For domestic water supply systems, pipes with diameters ranging from 20 to 63 mm are used. It is important to select the correct diameter to ensure optimal flow capacity.

- Pressure in the system. PPR pipes must meet the working pressure in the system. Therefore, pipes with appropriate wall thickness and pressure class should be chosen.

- Installation. PPR systems are installed using heat welding, providing reliable and tight connections. This installation method is simple and accessible, allowing for quick and efficient system installation.

- Resistance to ultraviolet light. When using PPR pipes outdoors, materials with additional protection against UV rays should be selected to avoid premature aging of the product.

PLM Products: Reliable PPR Pipes and Fittings

PLM offers a wide range of PPR pipes and fittings that meet modern quality standards. The brand's products combine reliability, durability, and ease of installation.

- PPR pipes for water supply. PLM pipes ensure stable operation of the water supply system, are corrosion-resistant, and withstand high temperatures.

- PLM PPR fittings. PLM fittings guarantee reliable and tight connections of pipes, preventing leaks and ensuring the stability of the system for decades.

PLM products are distinguished by high quality and meet the requirements of the modern market. By choosing PPR systems from PLM, you get a reliable solution for long-lasting water supply and heating.